Tools & Resources

Controlled Rolled XLERPLATE® - strong, tough and weldable

TMCP (or Thermo-Mechanical Controlled Processing) steels have been around in one form or another for the best part of four decades. Interest is growing in their particular combination of high strength, toughness and weldability.

A growing knowledge of the properties of TMCP steels is likely to overcome the reluctance by some industry segments to use them, and reduce confusion as to the properties of these steels. The pressure vessel industry in particular has potential to make greater use of TMCP steels. In order to make the most effective use of TMCP steels, this article outlines not only how they are produced, but also their advantages and disadvantages relative to normalised steels.

What are TMCP or controlled rolled steels?

TMCP is a collective term applied to several different processes for producing fine grained steels with high strength, good toughness and excellent weldability.

Production of TMCP Plate

Traditionally plate steel has been produced by "simple" hot rolling techniques. These steels relied almost entirely on their chemical composition to impart the desired properties such as strength and toughness. Further improvements to properties could be achieved by special heat treatments after rolling. Normalising, a process where the steel is heated to a temperature that results in a refining of the steel microstructure, has been common.

TMCP steels also rely on the steel chemistry but in a different way. Small additions (typically less than 0.06%) of grain refining elements known as microalloys are used to achieve a fine microstructure during the rolling process. Subsequent heat treatment is not required.

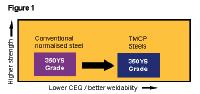

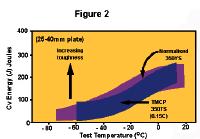

Production of a fine grained structure is the key to success with TMCP steels. This results in significantly higher strengths than would normally be obtained from low carbon steels, while at the same time producing a steel with higher toughness than that of normalised steels. In turn, because higher strengths can be produced from leaner steel chemistries (lower carbon equivalents), TMCP steels offer significantly improved weldability over traditional hot rolled steels of the same strength level. This is used extensively in the production of modern steels. In fact, a significant proportion of the AS/NZS 3678 - 350 XLERPLATE® grade is produced by a controlled rolled process.

After the original controlled rolled steels arrived, came a series of innovations taking into account not only the rolling, but the reheating of the slab before rolling and the accelerated cooling of the plate after rolling. These processes, produce steels of even finer grain structure and hence further improved properties.

Pros and Cons

The main advantage of TMCP steels is the unique combination of high strength with good toughness and weldability. This has led to their widespread use in critical applications such as offshore oil and gas platforms, pipelines, shipbuilding, high rise buildings and bridges.

The internal quality of these steels has also led to their extensive use in applications requiring high strength with excellent formability, the most common being the production of automotive components. Furthermore, TMCP steels offer the advantages of better surface quality and improved flatness when compared to normalised plate.

As with all materials, however, TMCP steels have their limitations. The major restriction is where hot forming may be required. Because hot forming is done at normalising temperatures, there is a change in the structure of the steel which can lead to reduced strength and toughness. These properties cannot be recovered upon cooling to low temperatures, because they are produced specifically during the original rolling process. Consequently, TMCP steels should not be used for applications requiring hot forming.

One advantage of TMCP steels over normalised steels is in weldability.

A Comparison of TMCP and Normalised Plate Steels

Normalised grades in general produce slightly higher toughness levels but this difference becomes academic considering that both result in toughness test values well in excess of the minimum values stipulated in the relevant material standards.

Conclusion

The single biggest attraction of TMCP steels is the potential for cost savings. A materials solution for a particular project will depend on the fitness for purpose, cost, and the total production cost. In this regard TMCP steels have some very real advantages over traditional steel types. Not only may the cost per tonne of TMCP steels be lower than normalised steels, but the savings obtained in fabrication may be greater.

The full potential of TMCP plate steels has yet to be realised. As designers increasingly appreciate the costs involved with fabrication, specifications should be altered to provide the option for a controlled rolled grade where appropriate.

By John Dryden