Tools & Resources

FAQs

Your search for Walling & Cladding returned 48 results.

Once installed, how should I look after my COLORBOND® steel?

Once installed, how should I look after my COLORBOND® steel?

Please view our page: Maintain COLORBOND® steel and ZINCALUME® steel

Can I use touch up paint on COLORBOND® steel?

Can I use touch up paint on COLORBOND® steel?

BlueScope Steel does not recommend the use of touch up paints on COLORBOND® steel. The manufacturing process that gives COLORBOND® steel its colour and gloss retention properties means that the surface weathers differently to air-drying paint. After weathering, the areas which have been touched up will look different and can leave a blotchy look.

How do I know I am getting genuine COLORBOND® steel, ZINCALUME® steel or GALVASPAN® steel?

How do I know I am getting genuine COLORBOND® steel, ZINCALUME® steel or GALVASPAN® steel?

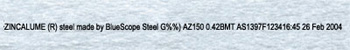

Where it's appropriate to place branding, products manufactured from COLORBOND® steel, ZINCALUME® steel and GALVASPAN® steel can be identified by the "branding" depicted below. Fencing made from COLORBOND® steel will be laser engraved with the COLORBOND® steel logo. also shown below.

Look for the brand that identifies the long lasting guaranteed performance of genuine BlueScope Steel.

What other building materials can I use alongside COLORBOND® steel? What metals are OK to use in contact with COLORBOND® steel and what should I avoid?

What other building materials can I use alongside COLORBOND® steel? What metals are OK to use in contact with COLORBOND® steel and what should I avoid?

Do not allow any metals other than aluminium, galvanised steel, ZINCALUME® steel or zinc to come into direct contact with COLORBOND® steel. Any direct contact between any other metals (eg. copper and lead) and COLORBOND® steel can result in corrosion. Especially take note of the following:

- Copper pipes and lead flashing should not come in direct contact with either ZINCALUME® steel or COLORBOND® steel. If the building design is such that water will flow from lead flashing onto ZINCALUME® steel or COLORBOND® steel, then the flashing should be painted.

- Water from copper pipes should not be directed onto COLORBOND® steel or ZINCALUME® steel.

- Stainless steel fixings and fixings containing copper should also not be used with ZINCALUME® steel or COLORBOND® steel.

- Fasteners conforming to AS3566 Class 3 or 4 are acceptable depending on the location of the product. If you have any questions, ask your supplier or contact us.

- This information is intended as a guide only. For more information, on our Corrosion Technical Bulletins, Download Corrosion Technical Bulletin CTB 12 - Dissimilar Metals.

What is the difference between COLORBOND® steel and imported steels?

What is the difference between COLORBOND® steel and imported steels?

The difference lies in performance requirements. COLORBOND® steel complies with a number of Australian Standards and was designed in Australia for Australian conditions. It is manufactured by BlueScope Steel, with a reputation second to none. COLORBOND® steel is not just powder coated steel. It is one of the most advanced steel products in the world, combining the outstanding anti corrosion performance of a ZINCALUME® steel base with a superior paint system. With imported steels you may not have all of these guarantees of quality.

Why can't I find any mention of the COLORBOND® steel colour I want? (ie Pale Terracotta, Torres Blue, Blue Ridge®, Ironbark, Bronze Olive or Saltbush).

Why can't I find any mention of the COLORBOND® steel colour I want? (ie Pale Terracotta, Torres Blue, Blue Ridge®, Ironbark, Bronze Olive or Saltbush).

Pale Terracotta, Torres Blue, Blue Ridge®, Ironbark, Bronze Olive or Saltbush is now discontinued as a standard colour for roofing & rainwater goods. Suppliers are still able to order non-standard colour from us, although price surcharges and/or minimum order requirements may apply. Please see our Find a Supplier page to find your nearest ten suppliers anywhere in Australia.

How do I fix a scratch on COLORBOND® steel?

How do I fix a scratch on COLORBOND® steel?

Our recommendation is not to touch up. Minor scratching will not affect the life of the sheet and is rarely obvious to a casual observer. Should damage be substantial, replace the sheet. We particularly recommend against the use of spray cans, as these can result in overspraying of surrounding areas. The problem might not be immediately obvious, but since overspray paint weathers at a different rate to the oven dried paint on COLORBOND® steel you'll eventually be left with an unsightly blemish on the sheet.

If I cut, drill or scratch COLORBOND® steel or ZINCALUME® steel, will it cause the exposed steel at the cut edge or scratch to rust?

If I cut, drill or scratch COLORBOND® steel or ZINCALUME® steel, will it cause the exposed steel at the cut edge or scratch to rust?

BlueScope Steel recommend 'cold cutting' coated steel products. If this recommendation is followed, these products will 'self heal', that is, the zinc in the surrounding coating will protect the newly exposed edge. How does this happen? In the presence of moisture, a reaction occurs between the zinc and the steel which results in galvanic protection of the exposed steel, thereby inhibiting corrosion. The degree of protection depends on the thickness of the coating (the amount of zinc), and this is taken into account when Building Standards are formulated.