Tools & Resources

FAQs

Your search for Roofing returned 107 results.

What is Thermatech® technology and how does it work?

What is Thermatech® technology and how does it work?

COLORBOND® steel incorporating Thermatech® technology provides a new level of thermal protection for houses & commercial buildings constructed in Australia. This leading edge technology works by absorbing less heat from the sun and therefore providing less heat in the roof space. This provides greater thermal comfort in buildings specified with COLORBOND® steel.

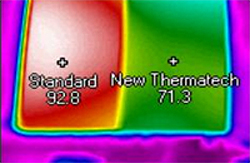

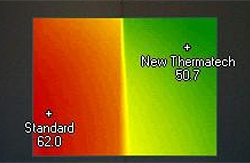

By absorbing less heat from the sun it has a lower surface temperature as illustrated below:

Woodland Grey® Comparison Laboratory Woodland Grey® Outdoors Winter

Next Generation COLORBOND® steel

Readings in Degrees Celsius

Next Generation COLORBOND® steel

Readings in Degrees CelsiusWhat are the advantages of COLORBOND® steel incorporating Thermatech® technology?

- When used in roofing applications, it improves the thermal performance of COLORBOND® steel across the entire colour range.

- Average reduction of solar absorptance across all colours is 5%

- Greatest improvement from reduced solar absorptance is in the dark colour range.

- Under BASIX colour classification – Sandbank® & Dune® move from a "medium" colour to a "light" despite no change to the actual colour.

- Similarly Wilderness®, Manor Red® & Jasper® move from a "dark" to a "medium" classification.

- In some parts of Australia this means real savings in the amount of

insulation that is required to meet building regulations, eg under

deemed-to-satisfy rules

- medium to light under BASIX = reflective foil at roof is not required.

- light colours under BCA = drop of R0.5 for roof insulation.

- very light colours under BCA = drop of up to R1.0 for roof insulation.

What should I do if I require more information on COLORBOND® Coolmax® steel?

What should I do if I require more information on COLORBOND® Coolmax® steel?

For more information about COLORBOND® Coolmax® steel, please visit our COLORBOND® Coolmax® steel page.

How does the coating technology work on COLORBOND® Coolmax® steel?

How does the coating technology work on COLORBOND® Coolmax® steel?

For a cool roofing product to perform best in hot sunny conditions it needs to have a high Total Solar Reflectance (TSR) and a high thermal emittance. COLORBOND® Coolmax® steel has both. It is cooler than ZINCALUME® steel and the rest of the COLORBOND® steel product range mainly because it achieves the highest TSR. It also has slightly higher thermal emittance than standard COLORBOND® steel because of its thicker paint system.

How does COLORBOND® Coolmax® steel technology affect Part J of the Building Code of Australia (BCA)?

How does COLORBOND® Coolmax® steel technology affect Part J of the Building Code of Australia (BCA)?

Currently COLORBOND® Coolmax® steel meets the highest level of concession available under the Deemed to Satisfy provisions of the BCA. Alternatively, the higher TSR value may be used within energy assessment software to improve performance, reduce insulation or compensate for underperforming elements of a building.

What colours is COLORBOND® Coolmax® steel available in?

What colours is COLORBOND® Coolmax® steel available in?

COLORBOND® Coolmax® steel is available in one colour, Whitehaven™.

Can I use the online Warranty Management System to apply for my warranty for COLORBOND® Coolmax® steel?

Can I use the online Warranty Management System to apply for my warranty for COLORBOND® Coolmax® steel?

Yes. As with all BlueScope Steel warranties, to estimate the warranty for your specific application or to apply for your warranty online, visit www.bluescopesteel.com.au/warranties.

Is COLORBOND® Ultra steel the same as COLORBOND® XSE steel?

Is COLORBOND® Ultra steel the same as COLORBOND® XSE steel?

COLORBOND® Ultra steel is not the same as it's forerunner, COLORBOND® XSE steel. There are several technical differences between the two products. However, COLORBOND® Ultra steel is designed to fulfill the same role in severe marine and industrial environments as COLORBOND® XSE steel did. Therefore, where you would have previously specified COLORBOND® XSE steel, you can now rely on COLORBOND® Ultra steel to provide the protection you need.

Does COLORBOND® Coolmax® steel have an R-Value?

Does COLORBOND® Coolmax® steel have an R-Value?

No. An R-Value is a term describing a material or system that provides a consistent level of resistance to heat flow. COLORBOND® Coolmax® steel roofing provides a varying level of resistance to heat flow into a building depending on the strength of the sun.

Can I walk on my roof made from COLORBOND® steel?

Can I walk on my roof made from COLORBOND® steel?

Normally it's OK to walk on a roof made from COLORBOND® steel. However safety precautions should be taken, including the wearing of soft rubber-soled shoes and any necessary precautions for working at heights. You should also take into account the manufacturer's recommendations about where to place your feet on the profile to prevent deformation.

Some roofs are designed to be 'non-trafficable' (meaning they're not designed to be walked on). This should be noted on designs, plans and is sometimes signposted.

If you are unsure whether a roof is trafficable, treat it as non-trafficable until you can confirm otherwise.

What difference does the thickness of the COLORBOND® steel make?

What difference does the thickness of the COLORBOND® steel make?

The thickness of sheeting is normally measured as its BMT (base metal thickness). For steel of the same grade and profile, a higher BMT generally means the sheet can span further between supports.

Care should be taken when referencing thickness because some manufacturers will quote Total Coated Thickness (TCT). This is the thickness of the total sheet and will be higher than its BMT (which measures only the thickness of the steel beneath any coatings). eg. 0.42mm BMT is the same as 0.47mm TCT.

Increased thickness will not increase the life of a product, and direct comparisons of BMT between profiles or steel grades cannot be made. The profile manufacturer should be able to provide you with spanning information for the profile and BMT you are using.

Soft (or lower strength) steels will generally be thicker than hard, high strength (or hi-tensile) steels, and are commonly used in applications where tight curving is required.